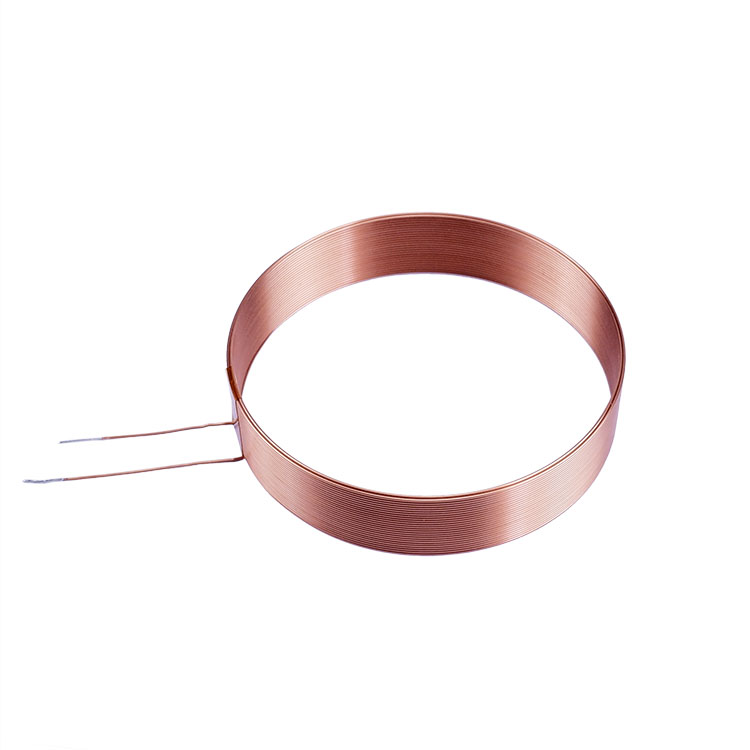

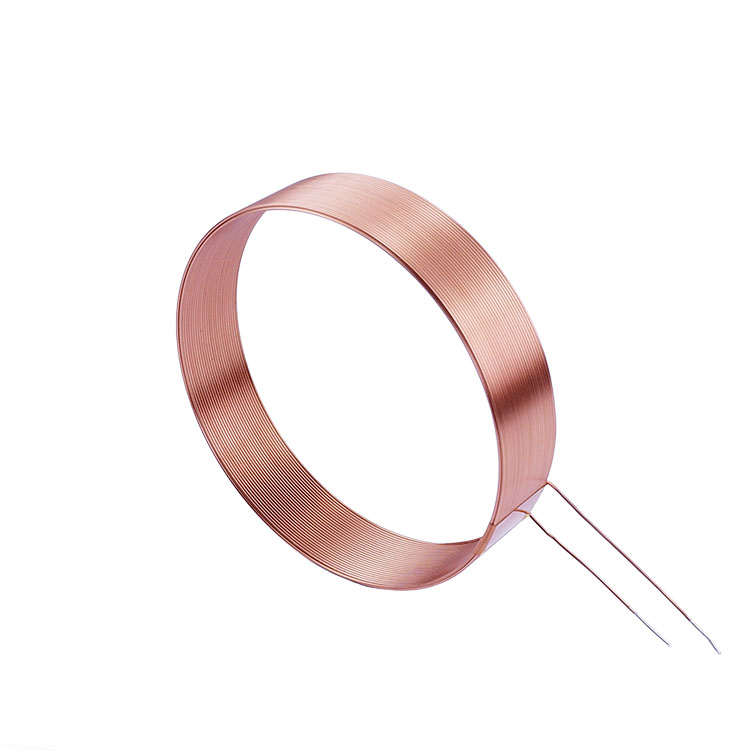

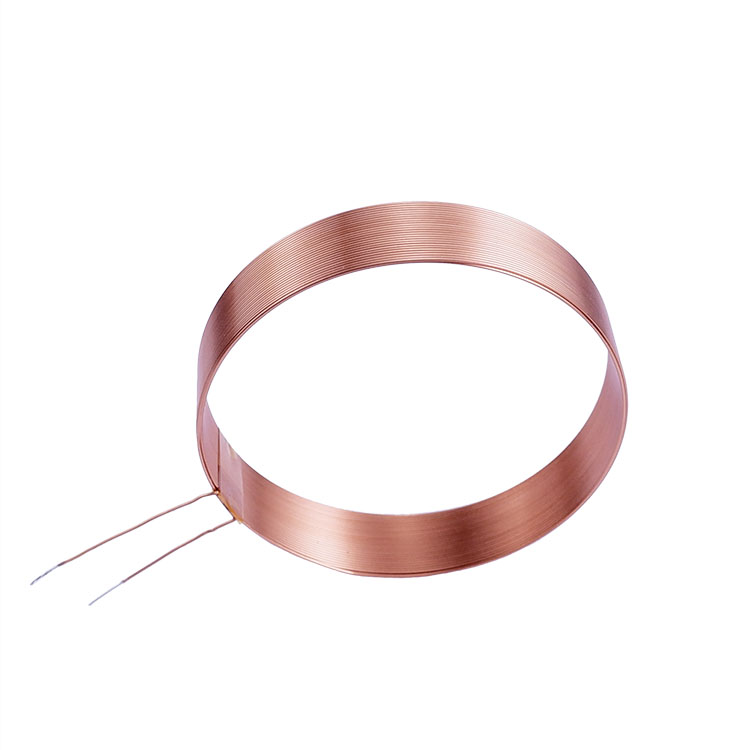

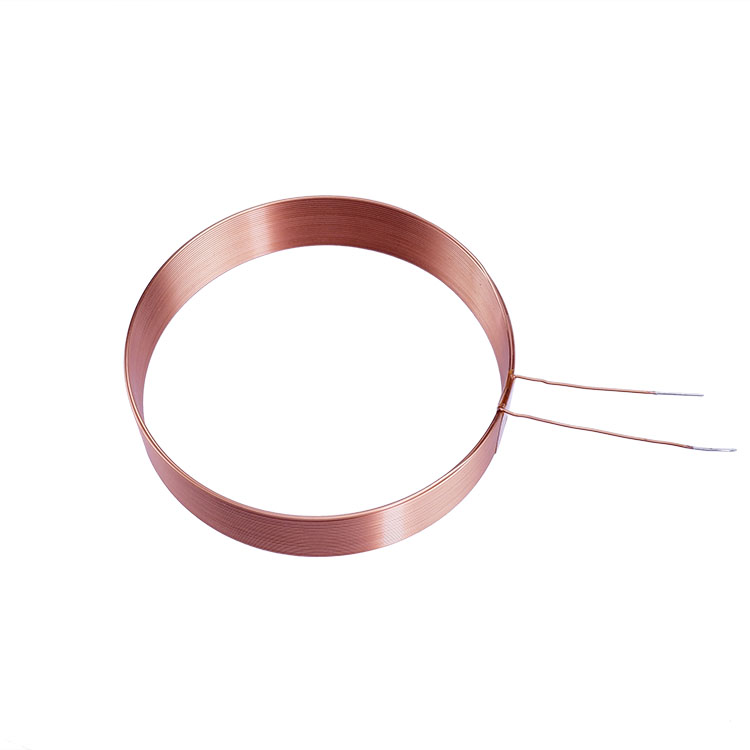

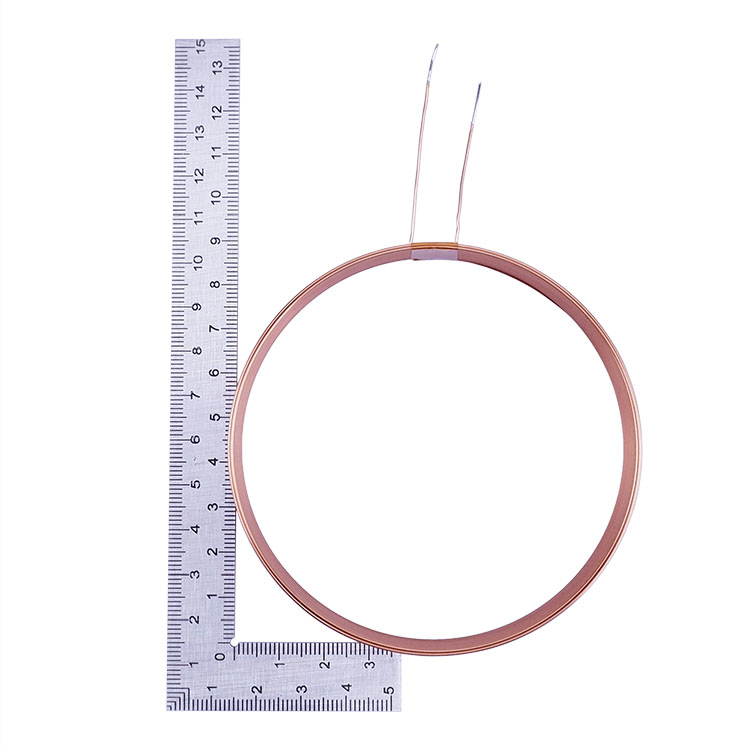

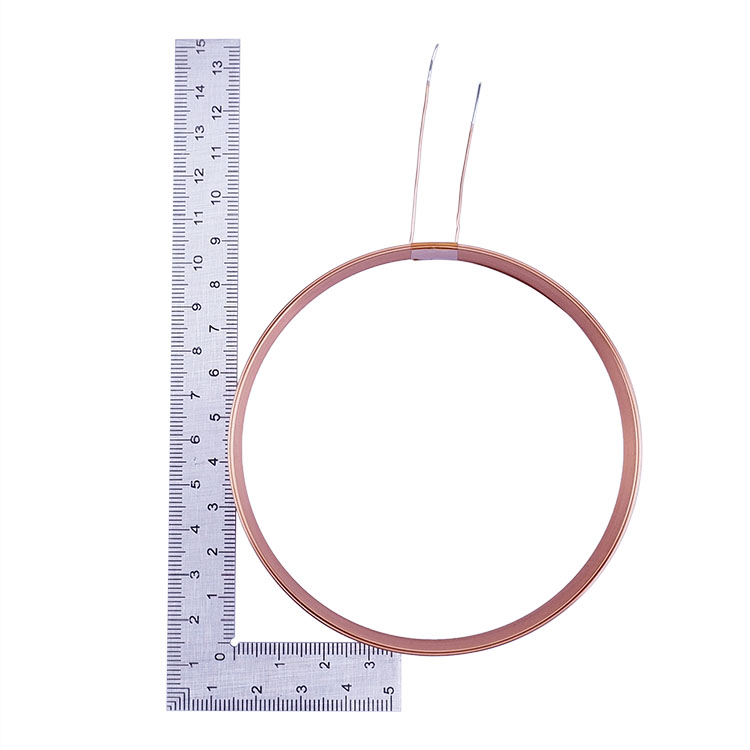

self-bonding wire inductor air coil for sensors

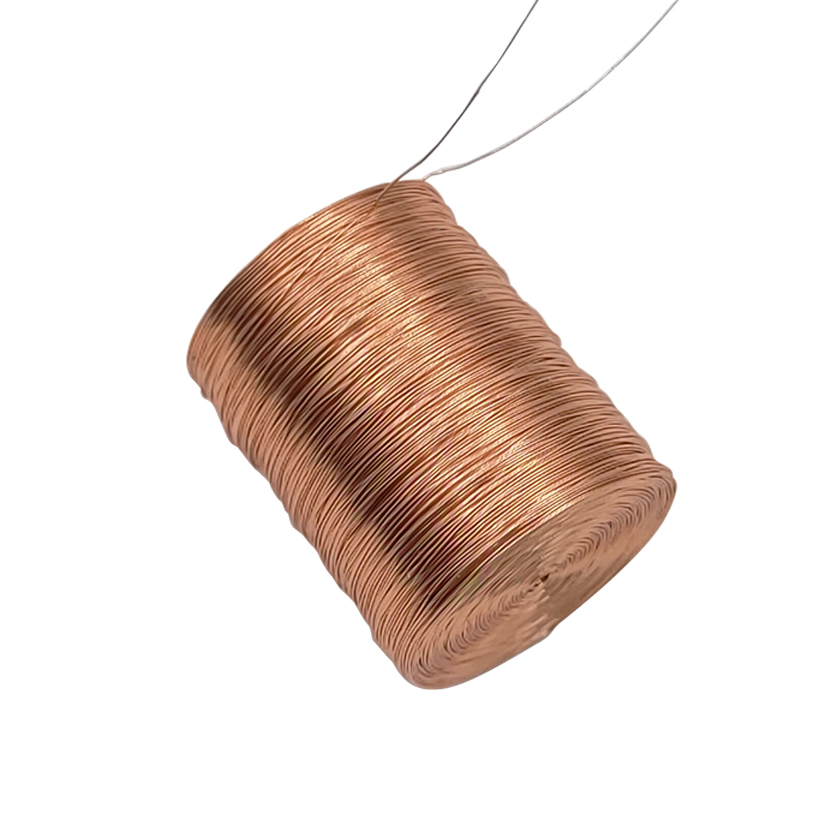

Construction of Air Core Inductors

An inductor is normally created by winding a wire or similar conductor in a coil. A conductor is also placed inside the coil to increase the inductance. An Air core inductor is one that does not include a ferromagnetic core. The term is used to represent inductors which only have air inside or consists of the wire coiled around a non conducting material such as PTFE or glass.

Advantages & Benefits

Air Core conductors have an advantage over conventional ferromagnetic core inductors that the inductance of the air core conductor does not depend upon the value of current it carries and also eliminates the iron losses from magnetic cores. They can also work at higher frequencies than normal due to lower losses and distortion. However the inductance for a coil is low since there is no magnification because of the core so a larger coil needs to be built to achieve a given inductance level. For this purpose they are widely used in high frequency applications where low inductance is required.

Application

1. Speaker Toys

2. IC-Card/ID-Card System

3. Electro-Mechanical displays

4. Antennas and remote control devices

5. Radio Frequency tag Electronic clock

6.Hearing aids

7.Monitor system

8. AC/DC Motor

FAQ

Q: If the small order quantity is workable

A:From the initial sample design of the spring to the mass production of the springs, we can quickly reach your manufacturing goals and immediately provide the best products because we have an excellent production management system and expertly trained technical personnel.

Q:Committed to high quality production

A:To keep Golden Eagle at the forefront of the industry, we have implemented a stringent internal quality control system and regularly import the latest manufacturing equipment and instruments. Through our precise manufacturing technology and expert mold making process, we provide our customers with the best products and service.

Q:How to make custom induction coil ?

A: Please provide the specification ,the drawing would be the best .

Q:What is the leade time for sample?

A: Usually it will takes about 7 -10 working days .

Q:What is the lead time for mass production ?

A: It’s flexible, based on your order qty and requirement.